SEMI-AUTOMATIC MACHINE FOR THE ASSEMBLY OF MOPS MADE OF BOTH COTTON AND SYNTHETIC MATERIAL.

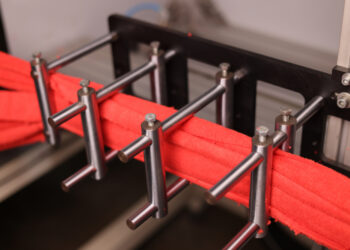

OMEGA 15 is an easy to operate machine for manufacturing mops of various sizes and shapes, using spools racks of both cotton yarns and synthetic material. An operator feeds the machine with plastic or metal sockets and staples and enables the assembly cycle, then the mop is pulled towards unloading area. OMEGA 15 automatically cuts the mops at desired lengths and ejects them.

The OMEGA 15 machine from Borghi India is designed for efficient and automated mop production, delivering consistent quality with minimal manual intervention. It features a robust spool rack capable of holding up to 60 cotton spools, ensuring uninterrupted feeding to the machine. Engineered to handle both cotton and synthetic mops, the Omega 15 offers flexibility in production along with variable mop length to meet diverse market requirements. With automatic cutting and automatic unloading, the machine streamlines the entire process, boosts productivity, and reduces operator effort, making it an ideal solution for high-volume mop manufacturers.

available to hold up to 60 cotton spools destined to feed the machine

available to cut non-woven material spools and feed the machine with non-woven strips

The finished products can be unloaded by conveyor belt (optional)

Standalone packaging unit available (see FLOW machine)

| Minimum mop length (mm) | 340 |

| Maximum mop length (mm) | 1200 |

| Maximum socket width (mm) | 200 (8 inches) |

| Output (mops/ hour) @500mm mop length | 300 |

| Power consumption (kW) | 0.5 |

| Air consumption | 12.3 cfm @ 5 bar |

| Weight (kg) | 750 |

| Dimensions (mm) | L – 3200 W – 1500 H – 1900 |